About Global Lift Used Forklifts South Dakota

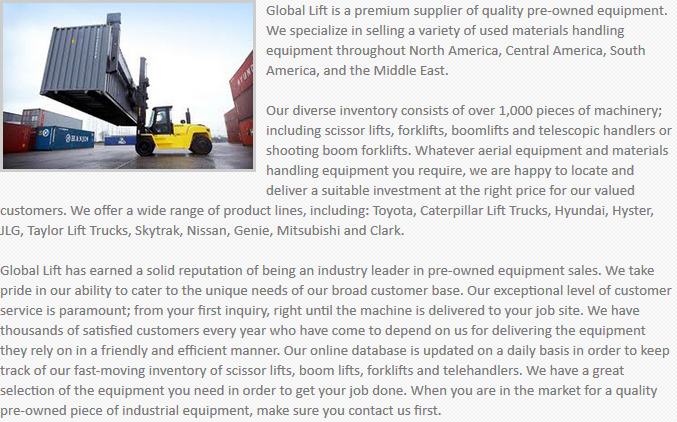

Global Lift South Dakota - Regardless whether you have a new forklift fleet or used forklifts, your machinery needs to be maintained to guarantee productivity and safety. Careless forklift operation can lead to added costs due to abuse and damage. There are simple ways to identify operator practices which indirectly contribute to expenses associated to the improper operation of Caterpillar forklifts or lift trucks. The following tips will really help you lessen operating costs while ensuring a long life for your equipment.

To be able to guarantee safety and productivity, your machine should be maintained whether it is a used forklift or a new forklift, . Careless forklift operation can result in additional costs because of damage and abuse. There are simple ways to identify operator practices which indirectly contribute to expenses related to the incorrect operation of Caterpillar forklifts or lift trucks. The following tips would help you lessen operating expenses while ensuring a long life for your equipment.

Causes Of Facility and Forklift Damage

Incorrect Forklifts. Selecting the right lift truck equipment for the application is essential for efficient and safe forklift performance. One of the most common mistakes is using the wrong type of forklift or options for the specific task. Machinery can suffer premature wear and tear. Components can be subject to failure. Check that the lift truck is fitted with the right tires and that they are not worn.

Incorrect Forklift Operating Practices. Improper forklift operating practices are a common cause of impact damage. Damage to machine, facilities or product could take place while navigating around products. A congested work area lends itself to impacts. Like for instance, pushing pallets, called "Bulldozing", could damage the transmission and wear tires.

Unsafe Forklift Lifting and Speeding. Improper lifting practices can result in equipment damage and personal injury. Common errors include lifting too high and traveling too fast. A load which is too heavy can cause the forklift to tip over. The driver must make sure that the forks are level.

In the US, 20,000 people are injured every year in accidents connected to the use of forklifts. And every year roughly one hundred deaths are caused by forklift accidents. Fortunately, proper training concerning maintenance and operation procedures could considerably reduce the risk of accidents. The following basic safety regulations and tips must be followed when using a forklift.

It is the job of the employer to make sure that the correct training program is given to the staff and that forklift operators are certified.. Training involves a combination of lectures, presentations, discussions and practical hands-on training. Reevaluation must take place every three years. Operators of forklifts must be up-to-date with current forklift safety regulations. Forklift training program content includes general workplace hazards, dangers of forklift operations, workplace surfaces and lighting, and dangers connected to operating the specific forklift which the employee would be utilizing. An employee must be at least 18 years old to use a forklift.

To make sure that the machine is functioning properly and safely, forklift inspection must be done each day. The inspection involves keeping a checklist of things and reporting any problems right away.

Having a clean and safe workplace is essential in the safe use of a forklift. A work place that is safe means establishing "traffic lanes" that are designated for forklift use only. Warning systems such as horns and flashing lights should be in place to indicate when there is a forklift approaching. Forklift docking stations should be inspected daily and kept in good repair.

General safety guidelines for forklift operation consist of ; respecting the load capacity of the forklift and never exceeding the maximum; making sure that there is enough clearance for the load; raising or lowering the load only while the forklift is stationary; and keeping legs, hands and arms inside the vehicle during operation.

A reach truck is required by businesses to help them get tasks done fast and efficiently. These elements that would enable the company to generate the most money at the end of the day. The Crown series of reach trucks offers you with more for your investment in various ways. Like for example, these machines deliver responsive controls together with smart traction. The ergonomics are state-of-the-art and offer the operator with a major edge.

These narrow aisle reach trucks can attain great capacities, visibility, heights and energy savings. Crown's machinery provide a lot of strong and dependable equipments which could endure harsh environments. They provide accurate load handling and increasing pallet moves with phenomenal travel and lift speeds. The reliability is well documented and results in driving overall costs down while offering industry-leading uptime and maintenance simplicity.

The SR 5000 Series, the RR 5700 Series as well as the RM 6000 Series make up the reach truck series manufactured by Crown. Particularly, the Crown RR 5700 delivers the best performance in the reach truck business for lift/lower and travel functions.

The RD 5700 is a really sturdy and helpful workhorse. This model offers the best use of space in the business, without taking away from operator comfort. The most advanced design and performance as well as innovative technology all come together in this series. Crown also provides their exclusive Access 123 Comprehensive System Control to offer great service team accessibility and operator control.

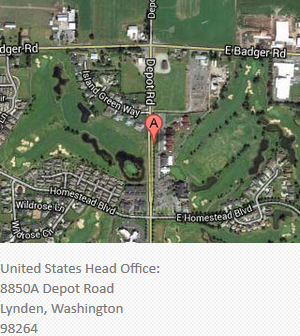

Contact Info

Fax: 1-888-029-0202

Fax: 1-888-029-0202

Questions or Comments